Sales Inquiry

Forged Swivel Clamps and Couplers: Benefits and Applications

When it comes to construction and scaffolding, certain components are vital for ensuring safety, stability, and efficiency. Among these essential parts are forged swivel clamps and couplers. While they might seem small, their role in securing scaffolding and other temporary structures is indispensable.

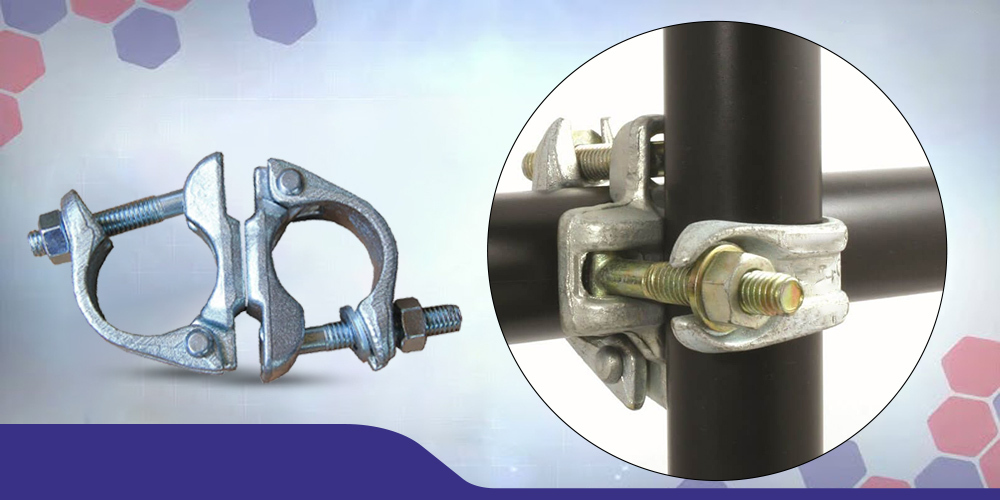

Forged swivel clamps, also known as couplers, are commonly used in scaffolding systems. They are specifically designed to connect two pipes or tubes at any angle, making them highly versatile. This flexibility allows them to be used in various industrial and construction applications, offering both strength and adaptability.

What Are Forged Swivel Clamps and Couplers?

Forged swivel clamps and couplers are robust components designed to connect two scaffolding tubes or pipes. Unlike rigid clamps, swivel clamps allow rotation, which makes them suitable for angled or irregular connections. These clamps are essential in scaffolding structures where pipes need to be joined at non-standard angles for increased flexibility and stability.

The term "forged" refers to how these clamps are manufactured. Forging is a process that involves shaping metal under high pressure to enhance its strength and durability. This makes forged swivel clamps far superior to their cast or welded counterparts in terms of reliability and performance.

How Are Forged Swivel Clamps Made?

Forging is a time-tested process that improves the metal's structural integrity. Here's a brief overview of how forged swivel clamps and couplers are made:

Material Selection: High-quality metal, often steel, is chosen for its strength and ability to withstand extreme conditions.

Heating: The metal is heated to a high temperature to make it malleable.

Shaping: Using precision dies and high-pressure machinery, the metal is shaped into the desired clamp or coupler design.

Cooling and Finishing: The forged component is cooled and then treated to ensure it meets safety and quality standards.

This process results in a product that is not only durable but also capable of handling heavy loads and environmental stress.

Key Benefits of Forged Swivel Clamps and Couplers

1. High Strength and Durability

Forged swivel clamps are known for their exceptional strength. The forging process aligns the metal's grain structure, making it highly resistant to cracks, fractures, and deformation. This ensures that the clamps can handle heavy loads and harsh conditions without compromising safety.

2. Flexibility in Use

Thanks to their swivelling design, these clamps can connect pipes at various angles. This makes them highly adaptable for complex scaffolding setups and other industrial applications where flexibility is crucial.

3. Corrosion Resistance

Many forged swivel clamps are treated with coatings or finishes that make them resistant to rust and corrosion. This extends their lifespan and ensures consistent performance, even in challenging environments.

4. Cost-Effective

While forged swivel clamps might have a higher upfront cost compared to other types, their long lifespan and reliability make them a cost-effective choice in the long run.

Common Applications of Forged Swivel Clamps and Couplers

Forged swivel clamps and couplers are widely used across various industries, including:

Construction: For scaffolding systems and temporary structures.

Industrial Maintenance: To set up temporary pipework and platforms.

Event Management: For constructing stages, lighting rigs, and other temporary installations.

Marine and Offshore: In challenging environments requiring robust and corrosion-resistant components.

Their versatility and durability make them indispensable in these applications.

Why Choose Forged Swivel Clamps?

When selecting components like swivel clamps, quality and reliability are paramount. This is where forged swivel clamps shine. The forging process ensures they are built to withstand heavy loads, extreme weather, and constant wear and tear.

Another significant advantage is that forged clamps can be customised to meet specific requirements. This ensures that every piece is perfectly suited to its intended purpose, offering unmatched precision and performance.

Trust Experts in Forging

For over 25 years, IQS Engineering Solutions has been at the forefront of forging high-quality components, including forged swivel clamps and couplers. As a fully integrated forging company, we manufacture half a million forgings every month, serving clients across the globe.

Our expertise lies in creating customised solutions tailored to client needs. Every clamp and coupler we produce meets stringent quality standards, ensuring the highest level of safety and performance. Whether you require standard or bespoke designs, our team is equipped to deliver products that exceed expectations.

Conclusion

Forged swivel clamps and couplers are the backbone of scaffolding systems, providing the strength, flexibility, and durability needed for a variety of applications. Their forged construction ensures superior performance, making them a trusted choice in industries worldwide.

If you're looking for reliable and high-quality forged swivel clamps, consider working with experts who have decades of experience in forging technology. With IQS Engineering Solutions, you're assured of top-notch products crafted to perfection.

.png)