Sales Inquiry

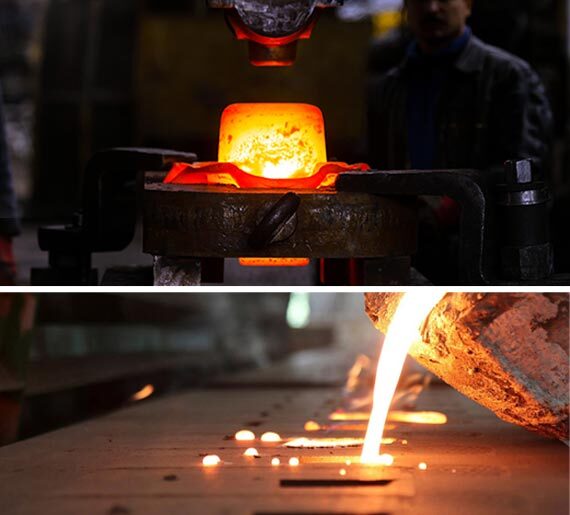

Streamlining Non Ferrous Forgings and Castings: IQS Tackles Operational Challenges

Table of Contents

2. Operational Challenges Faced by Clients

1. Lack of Order Visibility and Dispatch Information

2. Discrepancy Between Sample Quality and Bulk Supplies

3. Delays in Development and Delivery

4. Extended Lead Times

3. IQS Solutions for Operational Challenges

1. Enhancing Order Visibility and Dispatch Information

2. Bridging the Gap Between Sample Quality and Bulk Supplies

3. Mitigating Delays in Development and Delivery

4. Reducing Lead Times

4. Frequently Asked Questions (FAQs)

5. Conclusion

1. Introduction

2. Operational Challenges Faced by Clients

a. Lack of Order Visibility and Dispatch Information

Detailed Examination:

Clients operating in the fast-paced world of non ferrous forgings and non-ferrous castings face frustration when they lack visibility into their orders. Uncertainty about dispatch timelines and the whereabouts of orders in transit can lead to disruptions in supply chain management. This lack of real-time information hampers strategic planning and impedes the ability to respond promptly to market demands.

Solution from IQS Perspective:

Enhancing Order Visibility and Dispatch Information: IQS Engineering Solutions understands the critical role of transparency in client satisfaction. We have implemented state-of-the-art order tracking systems that provide real-time visibility into order status and dispatch information. Clients can now track their orders at every stage, from production to delivery, ensuring informed decision-making and optimized supply chain management.

b. Discrepancy Between Sample Quality and Bulk Supplies

Detailed Examination:

Clients often find themselves in a predicament when the quality of samples doesn't align with the bulk supplies. This discrepancy can lead to operational inefficiencies, rejections, and additional costs associated with rework. Ensuring consistency in quality from samples to bulk supplies is a pressing concern for clients in the non-ferrous industry.

Solution from IQS Perspective:

Bridging the Gap Between Sample Quality and Bulk Supplies: IQS Engineering Solutions places a premium on delivering what is promised. Our stringent quality control measures extend from the sampling phase to bulk production. Through advanced testing and inspection protocols, we ensure that the quality of bulk supplies aligns seamlessly with the high standards set by our samples. This commitment eliminates surprises, builds trust, and fosters long-term partnerships with our clients.

c. Delays in Development and Delivery

Detailed Examination:

The non-ferrous industry demands precision and timeliness. Delays in development and delivery can have cascading effects on downstream processes, affecting production schedules and market commitments. Clients grappling with unpredictable timelines face challenges in meeting their own deadlines, compromising their competitive edge.

Solution from IQS Perspective:

Mitigating Delays in Development and Delivery: IQS Engineering Solutions has implemented robust project management practices that prioritize timelines without compromising on quality. Our streamlined development processes, coupled with a proactive approach to issue resolution, ensure that projects progress seamlessly. By embracing agility and adaptability, we mitigate delays, enabling our clients to meet their commitments with confidence.

d. Extended Lead Times

Detailed Examination:

Extended lead times pose a significant challenge for clients in industries with dynamic market demands. The lag between order placement and delivery can impact inventory management, cash flow, and customer satisfaction. Clients operating in sectors with short product life cycles cannot afford prolonged lead times.

Solution from IQS Perspective:

Reducing Lead Times: IQS Engineering Solutions recognizes the importance of agility in today's fast-paced business landscape. We have optimized our production processes, reduced unnecessary lead time buffers, and implemented efficient logistics strategies. By embracing lean principles, we ensure that our clients benefit from shorter lead times, allowing them to respond swiftly to market changes and stay ahead of the competition.

3. IQS Solutions for Operational Challenges

a. Enhancing Order Visibility and Dispatch Information

Real-time Order Tracking Systems: IQS Engineering Solutions has invested in cutting-edge technology to provide clients with real-time visibility into order status and dispatch information. Our sophisticated tracking systems empower clients to monitor their orders seamlessly, enhancing transparency and facilitating strategic decision-making.

b. Bridging the Gap Between Sample Quality and Bulk Supplies

Stringent Quality Control Measures: IQS maintains unwavering consistency in quality from samples to bulk supplies. Our stringent quality control measures ensure that clients receive non-ferrous components that consistently meet the high standards set by our initial samples.

c. Mitigating Delays in Development and Delivery

Robust Project Management Practices: IQS employs robust project management practices and a proactive issue resolution approach to ensure seamless project progression, mitigating delays and instilling confidence in our clients.

d. Reducing Lead Times

Optimized Production Processes: IQS has optimized its production processes, embraced lean principles, and implemented efficient logistics strategies to reduce lead times, allowing clients to respond swiftly to market changes.

4. Frequently Asked Questions (FAQs)

Q1: How does IQS ensure real-time order visibility?

Answer: IQS employs cutting-edge tracking systems that provide clients with real-time visibility into order status and dispatch information, ensuring transparency and informed decision-making.

Q2: How does IQS maintain consistency between sample quality and bulk supplies?

Answer: IQS implements stringent quality control measures to ensure that the quality of bulk supplies aligns seamlessly with the high standards set by our initial samples.

Q3: How does IQS mitigate delays in development and delivery?

Answer: IQS employs robust project management practices and a proactive issue resolution approach to ensure seamless project progression, mitigating delays and instilling confidence in our clients.

Q4: How has IQS optimized its production processes to reduce lead times?

Answer: IQS has embraced lean principles, optimized production processes, and implemented efficient logistics strategies to reduce lead times, allowing clients to respond swiftly to market changes.

5. Conclusion

In the dynamic landscape of non ferrous forgings and cnoon-ferrous astings, operational challenges are not roadblocks but opportunities for innovation. IQS Engineering Solutions, committed to excellence, rises to the occasion, offering solutions that streamline processes, enhance transparency, and empower clients to navigate the intricacies of the industry with confidence. By addressing challenges related to order visibility, sample consistency, development delays, and lead times, IQS solidifies its position as a strategic partner, ensuring that every operational aspect reflects a commitment to unparalleled quality and efficiency.

.png)