Sales Inquiry

Non-Ferrous Forging & Casting Method To Designing & Planning Projects By IQS Engineering

Table of Contents

1. Introduction

2. Pain Points in Non-Ferrous Forging and Casting

3. IQS Solutions: A Comprehensive Journey through Design and Planning

4.Frequently Asked Questions (FAQs)

5. Conclusion

1. Introduction

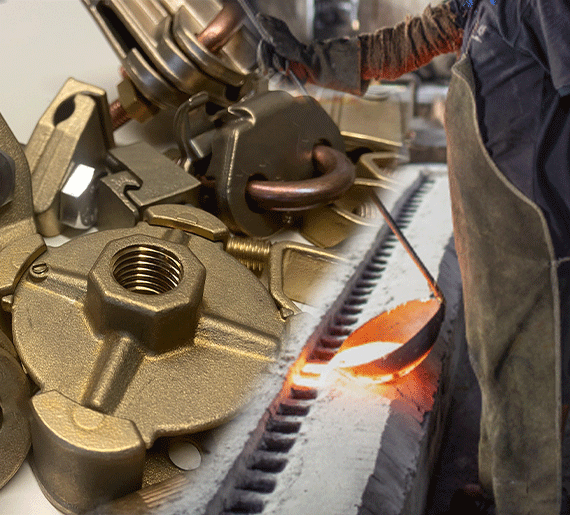

In the intricate world of non-ferrous forging and casting industry, the journey from concept to creation is laden with challenges. IQS Engineering Solutions empathizes with the hurdles faced by our clients, particularly in the areas of traceability of quality data and project planning. This blog delves into these pain points, offering an in-depth exploration of IQS's perspective and the innovative solutions we employ to elevate the standards of design and planning in non-ferrous forging and casting of components.

2. Pain Points in Non-Ferrous Forging and Casting

a. Lack of Traceability of Quality Data

Navigating the Challenge:

Clients often find themselves grappling with the lack of traceability of quality data for the parts supplied. The absence of a robust system for tracking and analyzing quality metrics can lead to uncertainties and hinder continuous improvement efforts. IQS Engineering Solutions understands the significance of traceability in ensuring consistent quality and reliability in non-ferrous forging and casting of components.

b. Absence of Proper Project Planning

Understanding the Struggle:

Another significant pain point in the non-ferrous forging and casting landscape is the absence of proper project planning. Inadequate planning can result in delays, budget overruns, and compromised quality. Clients need a seamless and efficient project planning process to ensure that their requirements are met with precision and timeliness.

3. IQS Solutions: A Comprehensive Journey through Design and Planning

a. Collaborative Design with State-of-the-Art CAD Software

Our Approach:

IQS commences the manufacturing process by fostering collaboration between your team and our design and engineering experts. Leveraging state-of-the-art CAD software and process simulation tools, we ensure a meticulous design and engineering phase. Our CAD/CAM engineering capabilities allow us to design detailed products and refine their geometry, tooling, and fabrication.

b. Proprietary Checklists for Requirement Mapping

Our Commitment:

Understanding your design and quality requirements is paramount to our process. IQS employs proprietary checklists to capture these requirements and meticulously maps them to our non-ferrous forging and casting process. This ensures that every step, from component modeling to engineering handover, aligns with your specifications, guaranteeing precision and satisfaction.

c. Seamless Project Planning and Execution

Our Solution:

IQS Engineering Solutions recognizes the significance of proper project planning. We have a well-established project planning framework that ensures a smooth journey from concept to delivery. Our captive CAD/CAM tool room plays a pivotal role in this, starting with 2D drawings, converting them into 3D models, and designing the necessary tooling. Experimentations and simulations take place in-house, allowing us to manufacture toolings that meet the highest standards.

Our project planning includes:

Component Modelling: Designing components with precision and detail.

Tooling Modelling: Crafting the necessary tooling for the manufacturing process.

Simulation for Optimization: Employing process simulation to optimize design and manufacturing efficiency.

Engineering Handover to Production: Ensuring a seamless transition from design to the production phase.

Upon confirming manufacturing feasibility, the design is released to the tool-room to manufacture the tool using the latest techniques, including:

Tool Manufacturing: Crafting tools with precision and cutting-edge techniques.

Sample Production: Producing samples for testing and approval.

Sample Testing and Approval: Rigorous testing to ensure the highest quality.

Production Handover: Transferring the design seamlessly to the production phase.

Our commitment to the latest CAD/CAM software, such as CNC Vertical Machining Center (VMC), Spark Erosion Machine, Surface Grinding Machine, and 3-D CNC Engraving Machine, ensures that our manufacturing experts and quality engineers work synchronically to reverse engineer parts and refine their design, tooling, and fabrication.

CNC Vertical Machining Center (VMC): Versatile machines used for metal cutting, shaping raw materials into precisioned surfaces.

Spark Erosion Machine: Utilized for metal disintegration through electrical charges, ensuring precision and quality.

Surface Grinding Machine: Provides components with a sophisticated finish, enhancing overall surface quality.

3-D CNC Engraving Machine: Utilizes advanced technology to cut and carve metals, transforming ideas into finished objects.

4. Frequently Asked Questions (FAQs)

Q1: How does IQS use CAD software in the design process?

Answer: IQS employs state-of-the-art CAD software to collaboratively design and engineer non-ferrous forging and casting of components. This ensures detailed products and allows us to refine their design, tooling, and fabrication.

Q2: How does IQS capture client requirements in the manufacturing process?

Answer: IQS utilizes proprietary checklists to capture client design and quality requirements, meticulously mapping them to our manufacturing process for precision and adherence.

Q3: How does IQS ensure seamless project planning and execution?

Answer: IQS has a well-established project planning framework, including a captive CAD/CAM tool room for 2D to 3D conversion, tool design, and in-house experimentation and simulations. This ensures precision from design to delivery.

Q4: How does IQS maintain traceability of quality data for supplied parts?

Answer: IQS implements a robust system for tracking and analyzing quality metrics, ensuring traceability and continuous improvement efforts in every step of our manufacturing process.

Q5: Why is project planning essential in non-ferrous manufacturing?

Answer: Proper project planning is crucial to avoid delays, budget overruns, and compromised quality. IQS ensures a seamless project planning process to meet client requirements with precision and timeliness.

Q6: What is the role of IQS's CAD/CAM tool room in project planning?

Answer: IQS's captive CAD/CAM tool room plays a pivotal role in 2D to 3D conversion, tool design, and in-house experimentation, ensuring the highest standards in project planning and execution.

Q7: How does IQS guarantee precision in design and engineering?

Answer: IQS guarantees precision through collaborative design, utilizing state-of-the-art CAD software and process simulation tools, ensuring detailed products that meet and exceed client specifications.

Q8: What is the significance of proprietary checklists in IQS's manufacturing process?

Answer: Proprietary checklists are crucial in capturing client requirements and mapping them meticulously to our manufacturing process, ensuring precision and client satisfaction.

Q9: How does IQS minimize delays in project execution?

Answer: IQS minimizes delays through a well-established project planning framework, including in-house experimentation and simulations, ensuring precision from design to delivery.

Q10: Why is traceability important in non-ferrous manufacturing?

Answer: Traceability is essential for consistent quality and reliability. IQS ensures traceability of quality data through a robust system, supporting continuous improvement efforts for our clients.

5. Conclusion

In the dynamic landscape of non-ferrous forging and casting, IQS Engineering Solutions stands as a beacon of innovation and reliability. By addressing the pain points of traceability of quality data and project planning, we not only meet industry standards but exceed them. Our commitment to collaborative design, meticulous requirement mapping, and seamless project planning ensures that every non-ferrous forging and casting of components becomes a testament to precision and excellence. IQS doesn't just manufacture; we engineer solutions that redefine the standards of design and planning in the Non-Ferrous Forging and Casting Industry.