Sales Inquiry

Connecting Rods - The Powerhouse Behind Your Engine's Performance

The internal combustion engine, the heart of most modern vehicles, is a complex machine with a multitude of moving parts working in perfect harmony. While pistons, valves, and crankshafts often receive the most attention, there is another important part that does not get much attention is the connecting rod. These seemingly simple components play a critical role in transforming the engine's power, making them the true powerhouse behind your engine's performance.

What is a Connecting Rod?

A connecting rod is a long, slender rod that acts as a bridge between the piston and the crankshaft in an engine. It translates the reciprocating (up-and-down) motion of the piston into the crankshaft's rotational force. This rotational force is then transmitted to the wheels, driving your car forward.

How Do Connecting Rods Work?

Imagine a piston rhythmically pumping up and down inside the cylinder. This linear movement wouldn't be very useful for propelling a car. The connecting rod connects to the piston on one end (usually through a piston pin) and the crankshaft on the other end. As the piston moves, the connecting rod pivots at the piston end and swings around the crankshaft journal (bearing surface). This translates the linear movement of the piston into the continuous rotation of the crankshaft, which ultimately drives the wheels.

Understanding the Anatomy of a Connecting Rod

A typical connecting rod is a long, slender rod with a larger end (big end) that connects to the crankshaft and a smaller end (small end) that connects to the piston. The big end is usually bolted together in two halves to allow it to be clamped around the crankshaft journal (bearing surface). The small end typically connects to the piston by way of a piston pin, also referred to as a wrist pin.

The Material Matters: Strength and Weight Considerations

Connecting rods are subjected to immense forces during engine operation. The exploding fuel mixture creates immense pressure, and the constant push and pull of the piston generates significant stress. To withstand these demands, connecting rods are typically crafted from high-quality materials that prioritize strength and durability. Here's a breakdown of some common options:

Steel Alloys:

The most widely used material, steel alloys offer an excellent balance of strength, affordability, and the ability to be forged into the desired shape. This makes them a versatile choice for most engines.

Aluminium Alloys:

For weight-conscious applications, aluminium alloys are a popular option. Their lighter weight can translate to improved engine performance, particularly in high-performance vehicles.

Titanium Alloys:

The pinnacle of connecting rod materials, titanium boasts an incredible strength-to-weight ratio. This makes it ideal for top-tier racing engines where minimizing weight is crucial. However, titanium's high cost and complex manufacturing processes make it less common for everyday vehicles.

The choice of material for a specific connecting rod depends on several factors, including the engine's application, budget constraints, and desired weight reduction goals.

Types of Connecting Rods

Not all connecting rods are created equal. Depending on the manufacturing process and intended use, there are several distinct types:

Cast Rods:

The most common and affordable option, cast rods are produced by pouring molten metal into a mold. They offer a good balance of strength and affordability, making them suitable for most stock engines.

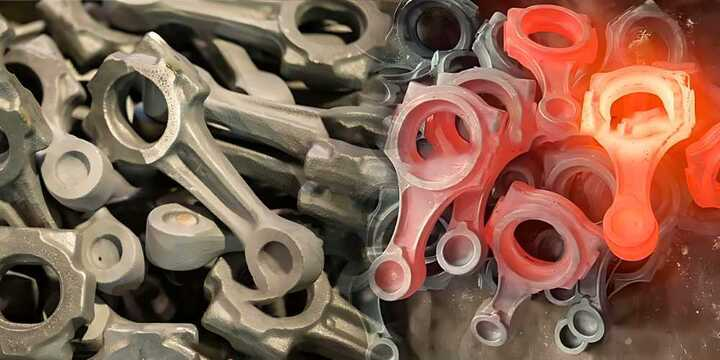

Forged Rods:

Forged rods are created by hammering and shaping heated steel. This process strengthens the grain structure, resulting in a stronger and more durable connecting rod compared to cast options. They are a popular choice for performance applications where higher engine stress is expected.

Powdered Metal Rods:

Powdered metal rods are formed by compressing metal powder at high pressure. This process allows for complex shapes and near-net shapes, reducing waste material. However, they may not be as strong as forged rods and are typically used in niche applications.

Billet Rods:

Billet rods are machined from a solid block of high-grade aluminium or steel. This precise machining process allows for the creation of lightweight and incredibly strong connecting rods ideal for high-performance engines. However, their high cost and complex manufacturing make them a less common option.

Optimizing Performance: Upgrading Connecting Rods

Seeking to push their engines to the limit, upgrading the stock connecting rods can be a worthwhile modification. Upgraded rods, often made from stronger or lighter materials, can provide several benefits:

Increased Engine Power:

Stronger connecting rods can handle the higher forces associated with increased power output, allowing your engine to perform at its full potential.

Improved Engine Response:

Lighter weight connecting rods reduce rotating mass, leading to a more responsive engine that revs quicker and delivers power more efficiently.

Enhanced Engine Durability:

Upgraded connecting rods can withstand the increased stress of high-performance applications, improving engine reliability and longevity.

However, upgrading connecting rods requires careful consideration. It's essential to choose the right material and specifications to ensure compatibility with your engine and avoid potential damage.

IQS Engineering Solutions understands the critical role connecting rods play in engine performance. Upgrade your engine with IQS Engineering Solutions' and experience the difference!